Research Highlights

Great Lakes Bioenergy researchers and collaborators engineered softwoods to incorporate a key feature of hardwoods. The resulting pine (shown here) processes more easily into pulp and paper.

Great Lakes Bioenergy research consistently results in new discoveries and new technologies. Here, we highlight high-impact research from all three of our research areas.

Natural genetic diversity of yeast aids in identification of genes involved in ionic liquid (IL) tolerance

In this study, researchers examined natural diverse isolates of Saccaromyces cerevisiae for tolerance to ILs and identified two genes associated with this outcome. Analysis of specific gene variants suggests that tolerance may be governed in part by the degree to which ILs can be pumped out of cells.

Ecosystem carbon balances on CRP grassland conversion to cropping systems

Bioenergy cropping systems can act as sinks or sources of atmospheric carbon dioxide, depending on the balance between the formation and decomposition of organic carbon.

Process and field-scale ethanol yield of five lignocellulosic feedstocks

GLBRC researchers processed and experimentally quantified ethanol production from five different herbaceous feedstocks: two annuals (corn stover and energy sorghum) and three perennials (switchgrass, miscanthus, and restored prairie). They determined that a range of plant types could be used in a lignocellulosic ethanol refinery without having a major impact on field-scale ethanol yield, which represents the ethanol production per land area.

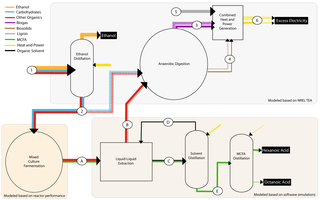

Lignocellulosic biomass conversion residue transformed into medium-chain fatty acid bioproducts

In this study, GLBRC researchers tested the hypothesis that microbial communities could be used to produce valuable compounds, such as medium-chain fatty acids (MCFAs), from lignocellulosic stillage. Techno-economic analyses showed that, at the productivity of MCFAs achieved in this study, valorizing lignocellulosic ethanol stillage to MCFAs could improve the economic sustainability of a biorefinery.

Switchgrass harvest date affects xylose utilization and ethanol yield

Unlike harvest of corn stover, which is linked to grain harvest, timing of harvest for energy grasses such as switchgrass is relatively flexible. In this study, GLBRC scientists aimed to determine if switchgrass harvest could be timed to maximize beneficial impacts on fermentation while avoiding production of harmful degradation compounds.

Optimized lignin analytics to improve biomass conversion efforts

As plant breeding programs embrace the idea of the biorefinery, lignin is emerging as a potential feedstock for commodity chemicals. To improve our understanding of lignin’s chemical structure and find potential bioproducts in lignin, GLBRC researchers developed a powerful analytical method to identify new and low-abundance compounds within the complex lignin biopolymer.

Biomass composition and lignin chemistry of energy sorghum

Comprehensive information about bioenergy crops’ composition under field conditions is needed to design optimal systems for production, harvesting, storage, and biorefinery operations. In this study, GLBRC researchers used near-infrared spectroscopy and nuclear magnetic resonance spectroscopy to characterize the composition of the energy Sorghum bicolorhybrid TX08001 grown in irrigated and non-irrigated field conditions, providing baseline information for future optimization.

Biological cleavage of lignin bonds

Optimizing how we break down biomass is critical to developing valuable chemicals from renewable materials such as plant lignin. GLBRC researchers found that the bacteria Novosphingobium aromaticivorans rapidly breaks the β-aryl ether bond commonly found in lignin, and that its enzyme, a Nu-class glutathione S-transferase, performs the critical step of removing the antioxidant glutathione.

Understanding the mechanism of mixed-linkage glucan synthesis and accumulation in the cell wall of grasses

Grass species, which are among the major renewable feedstocks supporting biofuel production, can provide an abundant source of mixed-linkage glucan (MLG), a glucose polymer. Improving biofuel crops by increasing sugar yields requires a thorough understanding of biosynthetic mechanisms. In this study, GLBRC researchers demonstrated that MLG is present in the Golgi apparatus, in post-Golgi structures, and in the cell wall; these findings provide new insight on how to modify the localization of MLG synthase to maximize production of MLG.

Combining pretreatment with modified poplar increases sugar yields

The copper-catalyzed alkaline hydrogen peroxide (Cu-AHP) deconstruction process is highly effective at pretreating a genetically-modified type of poplar called "zip-lignin" poplar, resulting in high sugar yields for biofuel fermentation even when inputs are reduced. Zip-lignin poplar incorporates weak linkages into lignin, the hard-to-process compound that gives plant cell walls their sturdiness, rendering the poplar especially amenable to the Cu-AHP deconstruction method.