Lignocellulosic biomass conversion residue transformed into medium-chain fatty acid bioproducts

Increasing the economic value of lignocellulosic stillage through medium-chain fatty acid production from residual organics

The Science

In this study, GLBRC researchers tested the hypothesis that microbial communities could be used to produce valuable compounds, such as medium-chain fatty acids (MCFAs), from lignocellulosic stillage. Techno-economic analyses showed that, at the productivity of MCFAs achieved in this study, valorizing lignocellulosic ethanol stillage to MCFAs could improve the economic sustainability of a biorefinery.

The Impact

One approach to achieve an acceptable level of profitability for lignocellulosic biorefineries is to produce valuable co-products, such as MCFAs, from stillage. In this study, GLBRC researchers identify a microbial community capable of producing MCFAs in a steady-state bioreactor. Furthermore, using techno-economic analyses, they demonstrate that the productivities observed during reactor operation result in a positive impact on the overall economics of lignocellulosic biorefining.

Summary

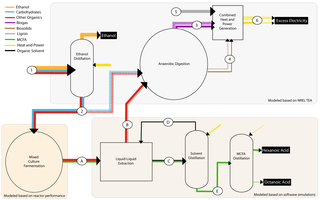

Lignocellulosic biomass is seen as an abundant renewable source of liquid fuels and chemicals that are currently derived from petroleum. When lignocellulosic biomass is used for ethanol production, the resulting liquid residue (stillage) contains large amounts of organic material that could be further transformed into recoverable bioproducts, thus enhancing the economics of the biorefinery. In this study, GLBRC researchers tested the hypothesis that a bacterial community could transform the organics in stillage into valuable bioproducts. They demonstrate the ability of this microbiome to convert stillage organics into MCFAs, identify the predominant microbial community members, and perform a techno-economic analysis of recovering MCFAs as a co-product to ethanol production. Steady-state operation of a stillage-fed bioreactor showed that 18% of the organic matter in stillage was converted to MCFA. Xylose and complex carbohydrates were the primary substrates transformed. During the MCFA production period, five major genera represented more than 95% of the bacterial community, including Lactobacillus, Roseburia, Atopobium, Olsenella, and Pseudoramibacter. To assess the potential benefits of producing MCFAs from stillage, the researchers modeled the economics of ethanol and MCFA co-production at MCFA productivities observed during reactor operation. The analysis predicted that production of MCFAs, ethanol, and electricity could reduce the minimum ethanol selling price from $2.15 gal-1 to $1.76 gal-1 ($2.68 gal-1 gasoline equivalents) when compared to a lignocellulosic biorefinery that produces only ethanol and electricity.

Contacts (BER PM)

N. Kent Peters

kent.peters@science.doe.gov, 301-903-5549

(PI Contact)

Daniel R. Noguera

dnoguera@wisc.edu

Funding

This work was funded by the DOE Great Lakes Bioenergy Research Center (DOE BER Office of Science grants DE-FC02-07ER64494 and DE-SC0018409), and by the National Science Foundation Graduate Research Fellowship Program under grant No. DGE-1256259.

Publications

Scarborough, M. J. et al. “Increasing the economic value of lignocellulosic stillage through medium-chain fatty acid production.” Biotechnology for Biofuels 11, 200 (2018) [DOI: 10.1186/s13068-018-1193-x].

Related Links

https://biotechnologyforbiofuels.biomedcentral.com/articles/10.1186/s13068-018-1193-x