Research Highlights

Great Lakes Bioenergy researchers and collaborators engineered softwoods to incorporate a key feature of hardwoods. The resulting pine (shown here) processes more easily into pulp and paper.

Great Lakes Bioenergy research consistently results in new discoveries and new technologies. Here, we highlight high-impact research from all three of our research areas.

Switchgrass and miscanthus long-term yield patterns reveal productivity declines

Researchers analyzed over 200 plantings of switchgrass and miscanthus at 12 sites across Michigan and Wisconsin with data spanning 5 to 15 years. Farm-to-gate economic analysis identified the most profitable rotations and economic relevance of fertilization.

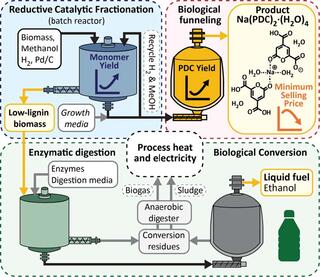

One-pot RCF process lowers cost of upgrading biomass to high-value products

Building on previous work evaluating stepwise processing, this study considers an integrated lignin-first biorefinery design that replaces the gamma-valerolactone (GVL) fractionation and hydrogenolysis with a single reductive catalytic fractionation (RCF) step and considers how the lignin and carbohydrate fractions would be utilized.

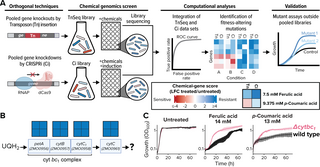

Independent chemical genomics approaches predict targets for increasing chemical tolerance

Scientists screened genome-scale CRISPRi (CRISPR interference) and TnSeq (transposon insertion sequencing) libraries of the Alphaproteobacterium Zymomonas mobilis against growth inhibitors commonly found in deconstructed biomass. By integrating the data from the complementary techniques they established an approach for defining engineering targets with high specificity.

Drought timing affects switchgrass metabolism, biofuel yields

Switchgrass is a promising bioenergy crop, due in part to its resilience to drought stress, but there is limited information on how drought affects metabolite profiles across developmental stages, in particular the distinction between core and developmentally specific physiological and metabolic drought responses. So researchers subjected plants to four watering treatments at specific developmental stages and measured the impact on growth and downstream ethanol yields.

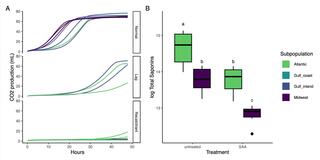

Switchgrass steroidal saponins that reduce fungal disease in the field inhibit yeast fermentation

Scientists measured variation in field fungal infection, specialized metabolite production, and fermentation efficiency in 102 genotypes of switchgrass and investigated methods for rescuing fermentation for poorly fermenting lines.

Engineered accumulation of protocatechuate in corn biomass can enhance biomanufacturing

Protocatechuate (DHBA) serves as a precursor for a wide range of valuable bioproducts. Crops can accumulate DHBA via expression of dehydroshikimate dehydratase (QsuB). This experiment sought to overproduce DHBA in plant biomass for downstream biological upgrading.

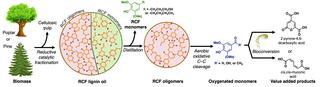

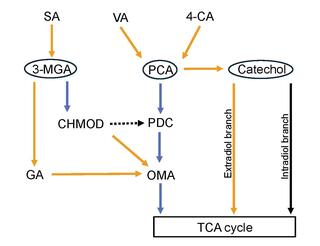

Cu-catalyzed oxidation cleaves C–C bonds in lignin-derived oligomers for biological funneling

Most methods for lignin deconstruction cleave carbon–oxygen bonds, resulting in suboptimal yields of aromatic monomers and formation of oligomers with intact carbon–carbon bonds that limit the yield of valorized products. This work demonstrates a copper-catalyzed aerobic oxidation process that converts oligomeric “waste” derived from reductive catalytic fractionation (RCF) of woody biomass into aromatic monomers. The resulting monomers are used as feedstock for biological funneling into bioproducts.

Systems-level analysis can improve aromatic funneling by N. aromaticivorans and other bacteria

Researchers performed a systems-level analysis of a LysR-family transcription factor in Novosphingobium aromaticivorans, which could inform engineering of commercially relevant bacteria that can remove toxic aromatics or metabolize them into industrial chemicals.

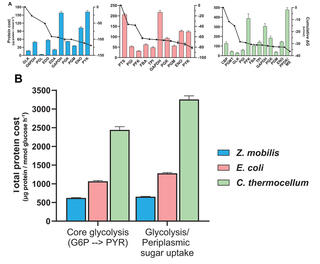

Living evidence reveals how thermodynamics shape enzyme investment in glycolysis

Computational studies predict that thermodynamically constrained reactions and pathways impose greater protein demands on cells, requiring a larger amount of enzyme to sustain a given flux compared to those with stronger thermodynamics. This study provides in vivo evidence that thermodynamic driving forces are a key parameter influencing the enzyme burden of metabolic pathways.

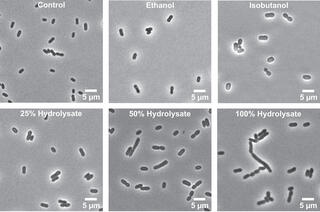

Lignocellulosic hydrolysate exposure elicits unique metabolic shifts in Zymomonas mobilis

Despite growing interest in Zymomonas mobilis as a biocatalyst, its physiological response to lignocellulosic hydrolysates remains poorly understood. Here researchers investigated the physiological response of Z. mobilis to ammonia fiber expansion (AFEX)-pretreated switchgrass hydrolysate using a systems-level approach integrating LC–MS/MS-based lipidomics and shotgun proteomics.