Optimizing for carbon storage: a new model for biorefineries

Bioenergy carbon capture and sequestration can increase biorefinery size and economy when incorporated with energy production factors in the making of biofuels and bioproducts.

The Science

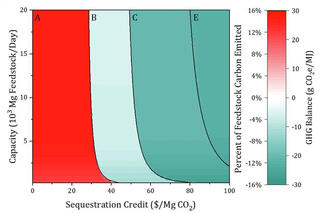

Widespread societal adoption of biofuels will require economically and environmentally sustainable biorefinery construction. With reduced emissions in mind, Great Lakes Bioenergy Research Center (GLBRC) scientists are now including estimations of the impacts of carbon capture and storage on such operations. They considered three sample feedstocks (corn, switchgrass, and poplar) and examined carbon capture from fermentation, biogas, and flue gas combustion emissions to calculate total bioenergy carbon capture and storage. They found that including carbon capture impacts economic viability of a biorefinery since it is interdependent with production methods. Altering these methods affects how much carbon dioxide is discharged into the atmosphere, which, in turn has an impact on the amount of capture that is feasible – and potential returns via carbon pricing. Ultimately, the simulations reveal that carbon pricing makes carbon capture an attractive option for biorefineries to scale up profitable production.

The Impact

This new work simulates carbon capture technologies and practices that allow a biorefinery to take advantage of a carbon marketplace. The model provides a novel measure of carbon as it makes its way from field to fuel, accounting for carbon losses and gains during planting of crops, fuel production, and carbon dioxide capture. Scenarios ultimately showed that larger cost-effective biorefinery operation can succeed when technologies are employed that don’t rely on grid electricity. This discovery opens the door for modeling profitable biorefinery operation to produce valuable fuels and chemicals while simultaneously capturing and sequestering carbon dioxide.

Summary

A biorefinery that utilizes nonfood crops instead of oil, gas or coal could provide sustainable methods of making fuels and other chemicals. GLBRC scientists incorporated carbon capture and storage technologies into models of how crop and pretreatment choices influence the economic viability of a biofuel refinery. They developed a model and performed thousands of individual calculations to determine the impact of carbon capture and storage technologies, feedstock choices, and pretreatment strategies on three outcomes: energy production, environmental impacts, economic benefits.

They found that the type of feedstock and the pretreatments used impact carbon emissions, which in turn affect the costs of carbon capture. With the inclusion of a carbon price, the right mix of these technologies together could increase the optimal capacity of a biorefinery fivefold, from 3000 Mg feedstock/day to 18,000 Mg feedstock/day when it produces its own electricity and keeps transport costs to a minimum. Future research will investigate the impacts of diversification of biorefinery output to other fuels and chemicals.

Program Manager

N. Kent Peters

Program Manager, Office of Biological and Environmental Research

kent.peters@science.doe.gov, 301-903-5549

Corresponding Authors

Caleb Geissler

Graduate Student, Princeton University

geissler@princeton.edu

Christos Maravelias

Professor, Princeton University

maravelias@princeton.edu

Funding

This work was funded by the DOE Great Lakes Bioenergy Research Center (DOE BER Office of Science DE–SC0018409).

Publications

Geissler, C., Maravelias, C., "Economic, energetic, and environmental analysis of lignocellulosic biorefineries with carbon capture." Applied Energy 302, 117539 (2021) DOI: 10.1016/j.apenergy.2021.117539