Different biomass pretreatment strategies give different hydrolysis, lignin yields from woody biomass

DOE Bioenergy Research Centers’ collaboration shows benefits and limitations of three pretreatment strategies.

The Science

Lignocellulosic biomass represents an enormous reservoir of reduced carbon that is a potential feedstock for the production of renewable fuels, chemicals, and polymeric materials. Pretreatment processes are needed to begin breaking down the biomass and make the plant sugars accessible for microbial fermentation into fuels and other products. Woody biomass such as poplar offers several potential benefits as a bioenergy feedstock, including high productivity, high bulk density (making it easier to transport and store), year-round availability, and suitability for widespread cultivation on land that may not be preferred for other agricultural uses. However, woody biomass is more resistant to breakdown than herbaceous feedstocks such as switchgrass. Scientists at the three original Bioenergy Research Centers (BRCs) – Great Lakes Bioenergy Research Center, Joint BioEnergy Institute, and BioEnergy Science Center (now the Center for Bioenergy Innovation) – collaborated to compare the performance of three pretreatment strategies on woody biomass. They evaluated three main criteria: 1) how easily the pretreated biomass could be further digested by cellulolytic enzymes, 2) how much of the starting mass was maintained through all the processing steps, and 3) suitability of the resulting lignin fractions for additional uses.

The Impact

This work represents a valuable advance in understanding the benefits and limitations of three different biomass pretreatment processes. While all three pretreatments highlighted in this study were capable of biomass fractionation, they demonstrated uniquely different functionalities in reducing biomass recalcitrance and achieving higher enzymatic hydrolysis yields for hybrid poplar while yielding a lignin-rich stream that may be suitable for further processing into co-products. These results suggest that different pretreatment strategies may give preferred outcomes depending on specific project goals and anticipated further use of the material (specifically the chemical uses of the produced lignin fractions).

Summary

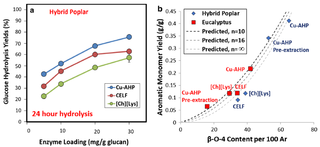

In this work, three pretreatments under investigation at the DOE BRCs were compared side-by-side to assess their performance on two model bioenergy hardwoods, eucalyptus and hybrid poplar. The pretreatments included co-solvent-enhanced lignocellulosic fractionation (CELF), pretreatment with an ionic liquid using potentially biomass-derived components (cholinium lysinate or [Ch][Lys]), and two-stage copper-catalyzed alkaline hydrogen peroxide pretreatment (Cu-AHP). For each feedstock, the pretreatments were assessed for how well they solubilized two abundant components of plant cells, lignin and xylan. Enzymatic hydrolysis yields of glucose and xylose were evaluated as a function of enzyme loading. Finally, lignins recovered from the pretreatments were characterized for polysaccharide content, molar mass distributions, β-aryl ether content, and response to depolymerization by thioacidolysis as a way to assess their potential for additional uses.

All three pretreatments resulted in significant solubilization of lignin and xylan, with the CELF pretreatment solubilizing the majority of both biopolymer categories. Enzymatic hydrolysis yields showed a strong, positive correlation to the lignin solubilized for the low enzyme loadings. All three strategies achieved high hydrolysis yields (~80%) for poplar and lower yields for eucalyptus. [Ch][Lys]-pretreated eucalyptus gave substantially lower hydrolysis yields, possibly due to soluble pretreatment-derived enzyme inhibitors that may have been carried forward into hydrolysis for this pretreatment.

The pretreatment-solubilized lignins exhibited significant differences in polysaccharide content, molar mass distributions, aromatic monomer yield by thioacidolysis, and β-aryl ether content. Key trends include a substantially higher polysaccharide content in the lignins recovered from the [Ch][Lys] pretreatment and high β-aryl ether content and aromatic monomer yield from the Cu-AHP pretreatment. For all strategies, β-aryl ether content was correlated with monomer yield and modification of lignin during pretreatment, particularly cleavage of β-aryl ether bonds, was detrimental to subsequent depolymerization.

Overall, the three pretreatments highlighted in this study showed different capabilities to reduce biomass recalcitrance and prepare woody biomass for further bioprocessing.

Contacts (BER PM)

N. Kent Peters

Program Manager, Office of Biological and Environmental Research

kent.peters@science.doe.gov, 301-903-5549

Corresponding Authors

David B. Hodge

Montana State University

david.hodge3@montana.edu

Eric Hegg

Michigan State University

eric.hegg@msu.edu

Funding

This work was supported by the Great Lakes Bioenergy Research Center, U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research under Award Numbers DE-SC0018409 and DE-FC02-07ER64494. The work was also supported by the Center for Bioenergy Innovation (DOE BER DE-AC05-00OR22725) and the Joint BioEnergy Institute (DOE BER DE-AC02-05CH11231).

Publications

A. Bhalla et al. “Performance of three delignifying pretreatments on hardwoods: hydrolysis yields, comprehensive mass balances, and lignin properties.” Biotechnol Biofuels (2019). 12, 213 [DOI: 10.1186/s13068-019-1546-0]

Related Links

https://biotechnologyforbiofuels.biomedcentral.com/articles/10.1186/s13068-019-1546-0