Greenhouse gas emission mitigation potential of chemicals produced from biomass

Making common industrial chemicals from plants instead of oil could lower greenhouse gas emissions by up to 94%.

The Science

An advanced biofuel refinery could produce chemicals and other products currently manufactured in an oil refinery with a lower cost to the environment. To provide more information on making environmentally conscious choices regarding the types of products made in such a biorefinery, Great Lakes Bioenergy Research Center (GLBRC) scientists modeled the production system of 25 industrial compounds, comparing estimated greenhouse gas (GHG) emissions in a biorefinery to the known GHG costs of making them in a petrochemical facility.

The Impact

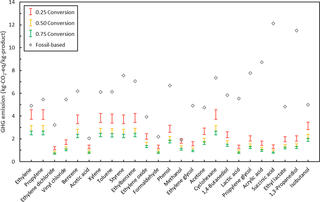

Results showed 24 out of the 25 modeled chemicals could be made in a biorefinery at a lower GHG cost than a typical oil refinery, cutting GHG emissions by 88% at the low end of efficiency and up to 94% under ideal manufacturing assumptions. Estimating the energy use necessary to take raw plant materials and turn them into biochemicals, the researchers found that products with high ratios of hydrogen to carbon and low ratios of oxygen to carbon tended to generate lower emissions in a biorefinery. This work allows potential biorefineries to optimize production and product choice for maximum GHG mitigation.

Summary

An efficient cellulosic bioenergy refinery would produce a wide range of chemicals using as much plant biomass as possible, while reducing the climate impacts. GLBRC scientists compared GHG emissions for the industrial production of 25 chemicals in a biorefinery versus a traditional oil refinery. The team evaluated the GHG emissions in each step of the process of converting plant matter into chemicals, including biomass pretreatment and hydrolysis, and conversion of sugars into final products. They then established three scenarios of biochemical production emissions, at low (25%), medium (50%), and high (75%) microbial conversion efficiency, and compared them to known GHG impacts stemming from production in a petrochemical facility. Results showed that even at a production efficiency of 25%, making these chemicals in a biorefinery represents an 88% reduction in GHG emissions over traditional petroleum sources. While this study modeled corn stover as its bioenergy crop, future iterations could include dedicated bioenergy crops such as switchgrass or poplar.

Program Manager

Shing Kwok

Program Manager, Office of Biological and Environmental Research

shing.kwok@science.doe.gov, (301) 903-2977

Corresponding Author

Christos Maravelias

Anderson Family Professor in Energy and the Environment and Professor of Chemical and Biological Engineering, Princeton University

maravelias@princeton.edu, (609) 258-5158

Funding

This material is based upon work supported by the Great Lakes Bioenergy Research Center, U.S. Department of Energy, Office of Science, and Office of Biological and Environmental Research under Award Number DE-SC0018409.

Publication

Huang, K., Peng, X., Kong, L., Wu, W., Chen, Y., Maravelias, C.T., “Greenhouse Gas Emission Mitigation Potential of Chemicals Produced from Biomass.” ACS Sustainable Chemistry & Engineering 9 (43), 14480-14487 (2021) [DOI: 10.1021/acssuschemeng.1c04836]

Links

Study: https://doi.org/10.1021/acssuschemeng.1c04836

Press Release: https://acee.princeton.edu/acee-news/study-ranks-best-chemicals-to-make-using-biomass/