For thousands of years, beer and wine lovers have been thankful for yeast, the ethanol-producing microbe that makes their favorite fermented beverages possible. Now, scientists at the Great Lakes Bioenergy Research Center (GLBRC) are working to improve yeast strains that could help make better biofuels.

During the brewing process, yeast microbes feed on wheat or corn mash. As they grow and use up available oxygen, ethanol is created as a byproduct.

The scientists hope to efficiently produce ethanol by feeding yeast with “food” that avoids any potential impact on human demand, such as cellulosic biomass. The challenge is finding a strain of yeast that can survive on this type of plant material and still produce biofuel efficiently.

“We want to change yeast’s appetite to an energy source that it never evolved to use,” says GLBRC Associate Scientist Trey Sato.

As part of the Improved Catalysts research group, Sato is teaming with Audrey Gasch, an assistant professor of genetics and GLBRC project lead, and Syd Withers, who directs the high-throughput microbial screening efforts of GLBRC’s Microbial Synthetic Biology (MiSynBio) lab. They are working to identify an evolved yeast strain that is compatible with the biofuel production process.

To create biofuels from plant materials like corn stalks, switchgrass or Miscanthus, a pretreatment process is needed to break down the tough cell walls before sugars can be released. While pretreatment is an efficient way to prepare plant sugars for fermentation, it can also generate toxic co-products that stress the yeast and impair their ability to produce ethanol.

“We want to find the yeast strains that aren’t affected by the toxins in pretreatment and will continue to produce ethanol efficiently,” Sato says.

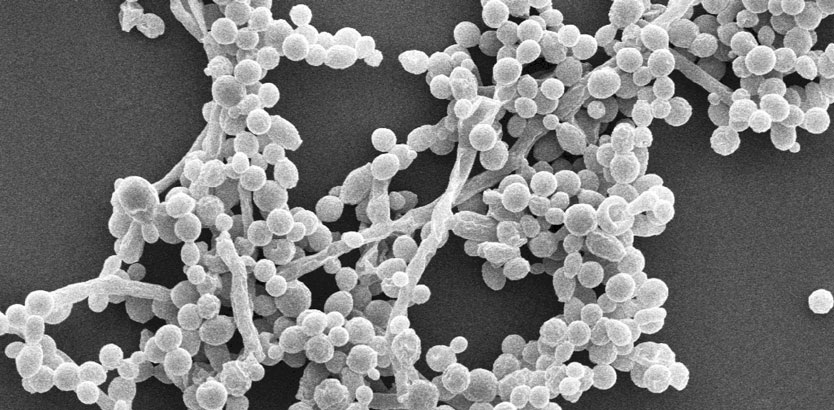

These microbes have evolved to live in a variety of environmental niches around the world, and the research team hopes to find strains compatible with pretreatment toxins. Sato and Gasch are focusing their investigation on the yeast species Saccharomyces cervisiae, which is most commonly used in industrial ethanol production. High-throughput robotic screening facilities that are part of GLBRC’s MiSynBio lab have helped Sato’s group narrow down thousands of different yeast strains to a handful of promising strains (see sidebar, A Look Inside GLBRC’s MiSynBio Lab). This collaboration allows them to shift their focus from macro-level to micro-level analysis.

“Improving yeast strains is an iterative process,” Sato says. “There’s great synergy in terms of expertise, and a lot more gets done than if it was just one group working on it.”

Building on the highly successful process used by the brewing industry, GLBRC researchers will continue to look to microbes like yeast for the renewable fuel solutions of the future.