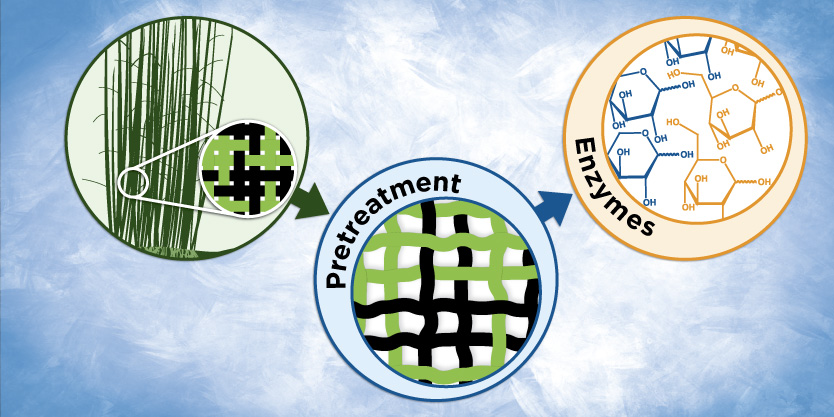

Just as people need to chew food to better access and digest the nutrients inside, mechanical and chemical pretreatment of plants disrupts the cell walls and allows access to the sugars within. Using ammonia, heat and pressure, a pretreatment method known as AFEX (ammonia fiber expansion) blasts open cell walls, allowing enzymes easier access to the sugar polymers that make up plant cellulose. Enzymes then break polymers apart into simple sugars for conversion to biofuel.

“We’ve come up with a less costly way of doing AFEX that we think is ready to commercialize,” says Bruce Dale, GLBRC deconstruction lead and MSU professor of chemical engineering and materials science.

Improvements to the AFEX pretreatment process have also reduced the need for costly enzymes by a factor of three. And if the team can push the technology further, accomplishing another three- or four-fold reduction, enzyme cost would no longer be a limiting factor in biofuel production.

As Dale’s team tinkered with different approaches to implementing this technology, they found that a modified approach to AFEX actually changed cellulose into a slightly different form that is five times easier for enzymes to break apart.

“We can understand in a much deeper way now how the AFEX process works, how it operates to produce digestible biomass,” Dale says. “Because we know that, we can do a much more rational job of picking the enzyme cocktails.”

Third Stop: Enzymes

In GLBRC’s early days, UW-Madison Bacteriology Professor Cameron Currie’s work with leaf-cutter ants shed light on how these remarkable insects actually grow food—in one of the world’s oldest instances of farming—by tending leaves that provide nutrients for a strain of fungi that is the ant’s dietary staple. Along the way, Currie discovered something else: the ant’s nests are home to a number of previously unknown microbes whose enzymes may help break down the leaves. Currie recognized this property as a potential asset in the attempt to break down cellulose for biofuel.

That research has given Currie insight into the way cellulose-degrading microbes like bacteria or fungi work. One thing he’s seen so far is that microbes rarely go it alone. “Microbes in nature do not occur in isolation,” says Currie. “They do not break down plant biomass in a pure culture. In many systems, like the ant system, you have increased success and ability to compete with other organisms through beneficial symbiotic associations.”

He predicts that within many of these symbiotic systems, combinations of microbial organisms are each producing different enzymes, and that these enzymes each play a part in the efficient breakdown of plant material.

The leaves and stalks of potential bioenergy plants are comprised of large quantities of cellulose, the most abundant organic compound on the planet. Cellulose is a polysaccharide, a long chain of tightly linked sugar subunits that must be broken down into simple sugars before they can be processed into biofuel.

The ability of enzymes to grow on pure cellulose and break it down into simpler sugars is a very unique capability—one that helps Currie and other GLBRC researchers substantially narrow the field of research subjects.

“If taking apart cellulose was easy, there wouldn't be any trees around,” says Brian Fox, a UW-Madison professor of biochemistry who co-leads GLBRC’s deconstruction research.

From the 3,000 contenders that Currie and his team have sitting in cold storage, only 50 pass the cellulose test.

After making the first cut, Fox wants to know more about how the remaining bugs will function, including how they hold up in hostile environments. Are they picky, or can they withstand a variety of conditions?

After scouring natural environments and narrowing down the potential players, GLBRC deconstruction researchers have focused their attention on a novel microbe called Streptomyces sp. ActE (ActE).

Isolated from the community of wood-boring wasps, ActE seems to have an evolutionary advantage that makes it great at breaking down cellulose.

“The wood wasp is an interesting thing for us because it's very specific,” Fox says. “For ten million years, they have been attacking pine trees, offering the potential to developed a specialized approach to deconstructing woody materials. "

From the start, GLBRC researchers realized that this bug had potential. Performance measures have shown that ActE is just as capable at breaking down cellulose as T. reesei, a fungus that is used heavily by industry as a source of biofuels enzymes.

Digging into ActE’s unique characteristics has surfaced an interesting discovery: ActE uses oxygen to metabolize cellulose.

“This realization is a brand new area in the whole of biofuels research. It’s a new paradigm,” Fox says.

Now that Fox’s team is intently focused on ActE, they’re using genomic tools like sequencing, microarrays and proteomics to learn why this bug seems to do its job so well. Since ActE secretes its proteins, studying how individual enzymes function is relatively simple.

Once specific ActE enzymes are isolated, Fox can look at each one and measure its activity, stability and impact on the overall effectiveness of the enzyme cocktail. “If protein X is the weak link, that's a target for engineering.”

Currie and Fox are working to deliver newly characterized enzymes to other GLBRC researchers who study chemical pretreatment methods, solve 3-dimensional crystal structures to better understand how the enzymes work and use a robot to create enzyme cocktails that release sugars from plant biomass. This robotics platform, GENPLAT, runs through an impressive 96 tests at once, allowing Jonathan Walton, an MSU plant biologist and GLBRC colleague, and his team to quickly evaluate new combinations of enzymes on different types of bioenergy crops.

“ActE provides a natural example that is easy to grow in a test tube, and so provides many attractive starting points for further study,” Fox says. “As we begin to understand how it really works, we can then take that knowledge and improve on it.”