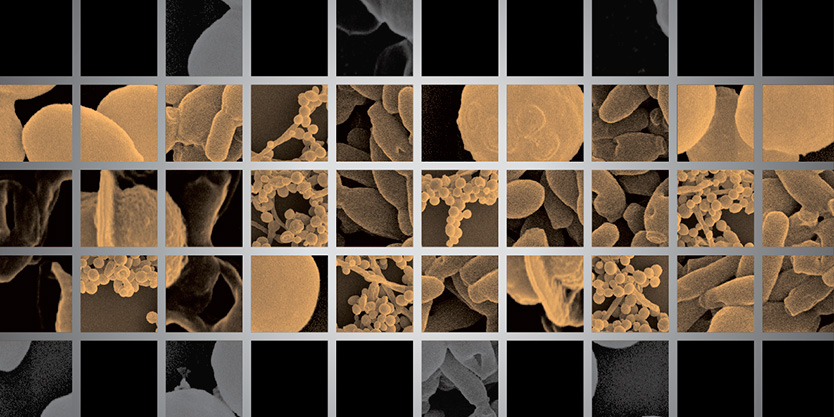

Once biomass has been pretreated and the sugars released, GLBRC scientists work with bugs like yeast and E. coli to optimize the way they churn through sugars and ferment them to produce fuels.

Even though S. cerevisiae, an industrial yeast that has been used by brewers for centuries, is great at chewing through glucose, it hasn’t had much of an appetite for the five-carbon sugars like xylose—the second most abundant plant sugar—that make up a good part of the plant cell wall. That is, until now.

“Strains of yeast that are currently used for biofuel production can only convert xylose to ethanol very slowly and inefficiently,” says Dana Wohlbach, a UW-Madison genetics researcher and GLBRC postdoc. “But the more sugars a yeast can consume, the better, since more sugar consumption means more ethanol.”

Researchers have identified a species of yeast found in bark beetles that is able to efficiently use xylose. After engineering that species’ xylose-friendly genes into an industrial yeast, researchers found that the industrial yeast, too, could use xylose along with other sugars—a development that could significantly increase the amount and speed with which biomass sugars can be converted to biofuels.

Although encouraging bacteria and yeast to act as miniature biofuel factories shows incredible promise, GLBRC is putting a few other bets on the table.

“Ethanol will probably continue to have a place in the automotive industry in the U.S. and around the world for decades,” says GLBRC Director Tim Donohue, “but it is never going to be an acceptable biofuel for diesels or aviation or the shipping industry.”

Donohue is eager to expand the Center’s suite of fuels so that if an airline or shipping company comes knocking, they’ll find options to help them meet ambitious industry goals for reducing petroleum use. (The airline industry, for example, has committed to achieving carbon-neutral growth by 2020, as stated by the International Air Transport Association.) These industries are demanding ready-to-use fuels that can be “dropped in” to existing infrastructure such as engines, gas tanks and pipelines.

Demonstrating a vote of confidence in the emerging biofuels industry this December, U.S. Navy Secretary Ray Mabus and U.S. Department of Agriculture Secretary Tom Vilsack announced that the Defense Logistics Agency (DLA) signed a contract to purchase 450,000 gallons of advanced drop-in biofuel, the single largest purchase of biofuel in government history.

While the Navy fleet alone uses more than 1.26 billion gallons of fuel each year, this biofuel purchase is significant because it accelerates the development and demonstration of a homegrown fuel source that can reduce America's, and our military's, dependence on foreign oil.

"This unprecedented fuel purchase demonstrates the Obama Administration's commitment to seeking energy security and energy independence by diversifying our energy supply," stated Secretary Mabus.

To meet this massive call for drop-in fuels, researchers at the GLBRC are leveraging knowledge about E. coli bacteria by applying new synthetic biology approaches to generate the cellulosic biofuel technologies needed.

“In an ideal world, you could go to the gas station and fill up your car or truck with a biofuel that is indistinguishable from today’s petroleum derived fuels,” says Brian Pfleger, GLBRC project leader and UW-Madison assistant professor of chemical and biological engineering. “If we can successfully develop methods of producing fuels from cellulosic biomass, we can reduce the need for new fueling infrastructure and the problems associated with that enormous change.”

Pfleger’s team is working to produce hydrocarbons that can work in today’s engines and fuel pipelines. As part of their quest to create a “green diesel,” researchers are relying on modified bacteria to convert sugar into building blocks that can later be used to create a variety of new products, including fatty acids, oils or biodiesel.

“Oils are an ideal source for biofuels, because they can be used for multiple forms of fuel, including biodiesel,” says Steve Slater, GLBRC scientific programs manager. “While ethanol cannot be used in heavy transportation diesel engines, oils can be modified for diesel and gasoline replacements.”

Using the same sugar building blocks that can be upgraded into oils for fuel, researchers also hope to extend the technology in the future to create chemicals, bioplastics and other commercial products.