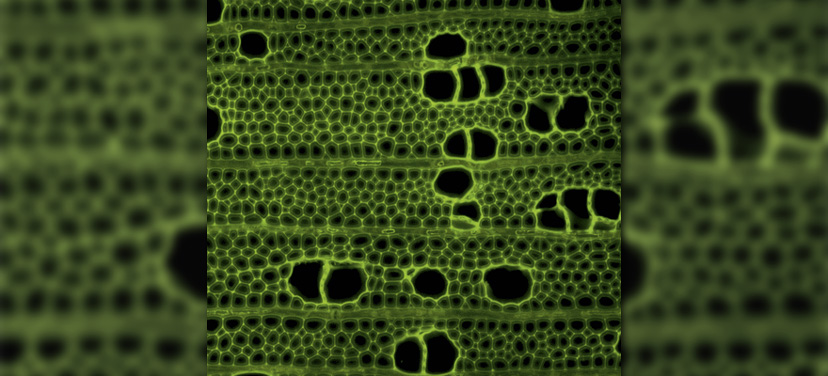

For decades, John Ralph’s group has been focusing its expertise in biology, chemistry and engineering on one of the most persistent hurdles to a bio-based fuel economy: lignin. As the organic polymer that binds plant cell, vessel and fiber cell walls, lignin resists chemical and enzymatic processing and thus acts as a structural barrier to converting biomass into liquid fuels.

So-called “second-generation” biofuels, which derive from dedicated energy crops such as switchgrass or poplar trees, are all lignocellulosic, meaning their woody cell walls contain lignin polymers. Ralph, a University of Wisconsin–Madison professor of biochemistry and biological systems engineering and the Plants Leader within the Great Lakes Bioenergy Research Center (GLBRC), recently collaborated with researchers at Michigan State University, Ghent University in Belgium, and INRA in France on a field trial of lignin-modified poplar trees to measure any increase in ethanol yields.

The group’s paper, “Improved saccharification and ethanol yield from field-grown transgenic poplar deficient in cinnamoyl-CoA reductase,” appeared recently as a cover article in the Proceedings of the National Academy of Sciences, and reports on a field trial of poplars in which cinnamoyl-CoA reductase (CCR), an enzyme known to play an important role in lignin biosynthesis, is genetically down-regulated or decreased.

Preliminary data on the group’s lignin-modified poplars had been encouraging. “Basic mechanistic data and performance data from green-house grown poplars and Arabidopsis suggested that the CCR lines’ improved performance could be due to structural changes to lignin, in addition to lignin reduction,” Ralph says.

Although the extent to which lignin was suppressed varied between poplars, the study showed that down-regulating CCR resulted in a 20 percent higher ethanol production from un-pretreated biomass and, in the strongest cases of suppression, a 160 percent higher yield.

“We applaud our European collaborators for undertaking these extensive, replicated, and difficult field trials on one of the most promising lignin-altered lines,” Ralph says. “These trials provide real-world productivity and conversion data comparisons while at the same time beginning to address sustainability and environmental issues.”

The use of strong CCR down-regulation, however, also had an adverse effect on poplar yield. The lignin-modified trees grew less quickly than their non-modified counterparts. Further studies will likely focus on overcoming the yield penalty associated with CCR down-regulation, or on using a different enzyme, such as the CAD-enzyme, to achieve a more uniform suppression of lignin. Both Boerjan and Ralph are optimistic that further refinements to the paper’s method could improve the un-pretreated ethanol yield of poplar by 50 to 100 percent.

“A number of current and emerging lignin-altered lines have the potential to lower the severity of expensive biomass pretreatment, which would improve the overall energy balance and sustainability of converting biomass to biofuels,” says Ralph.

This research was funded partially by The Great Lakes Bioenergy Research Center (GLBRC), one of three Department of Energy Bioenergy Research Centers created to make transformational breakthroughs that will form the foundation of new cellulosic biofuels technology. For more information on the GLBRC, visit www.glbrc.org.