Tom Jeffries is a scientist in the truest sense of the word. His passion for studying biofuel is evident as he describes is 40-year career in the field, yet he emphasizes that he is careful not to favor one technology over another.

Instead, Jeffries relies on pragmatism to guide his research.

"Yeast are very resilient, there is a long history of their commercialization, and we understand the technology,” he says of yeast’s role in converting plant biomass to ethanol.

"Making it work economically is what's hard."

Jeffries, a Great Lakes Bioenergy Research Center scientist and University of Wisconsin-Madison bacteriology professor, has recently published a paper describing a new type of yeast that can ferment plant sugars to ethanol much more efficiently than other species. He thinks this microscopic critter could have a big impact on economical commercial biofuel production.

"Yeast are probably the most practicable way to get renewable fuels today,” Jeffries says.

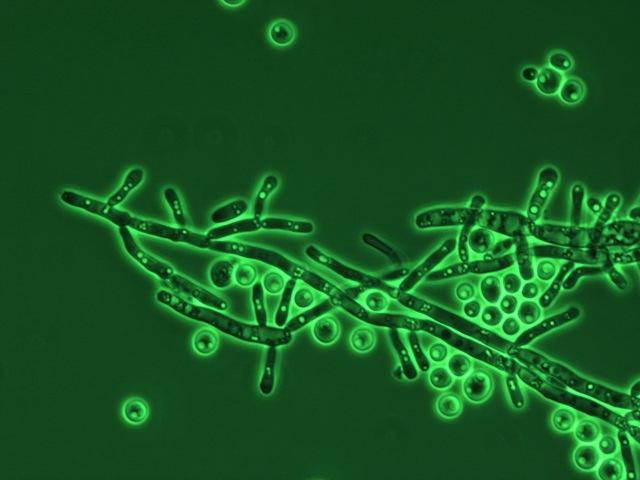

Though yeast may not be the first thing to spring to mind when the subject of renewable energy is raised, these single-celled organisms are metabolic powerhouses. For biofuel researchers, Saccharomyces cerevisiae is nothing short of a household name thanks to its appetite for sugars from cellulosic—or non-food—plant material, and its ability to ferment them to ethanol.

But Jeffries’ interest has been captured by Spathaspora passalidarum, a highly specialized yeast species that grows in the bellies of wood-boring beetles. Because it plays a key role in the beetles’ digestion, S. passalidarum is naturally adapted to fermenting sugars found in wood that S. cerevisiae can’t process. While S. cerevisiae is able to ferment simple sugars like glucose and sucrose, S. passalidarum is also able to convert xylose, cellobiose, arabinose, and galactose to ethanol.

Finding an organism that can ferment xylose is a particularly important breakthrough for biofuel researchers, because xylose is an essential building block of hemicellulose—a polymer that makes up about 20 percent of most plants.

"People tend to think that yeasts are all the same, but they're not,” says Jeffries. [S. passalidarum] can use cellulosic and hemicellulosic sugars efficiently, whereas S. cerevisiae cannot unless it has been genetically engineered.”

Jeffries hypothesizes that these two yeast taxa diverged as long ago as 180 million years, around the time that flowering plants began to evolve. It is possible that while S. cerevisiae evolved in association with insects that consume sugars from flowering plants, S. passalidarum instead took up residence in the mid-guts of passalid beetles—large insects of an inch or more in size that inhabit rotting logs. Their unique habitat requires S. passalidarum to ferment sugars found in the wood pulp ingested by their beetle hosts.

"[S. passalidarum] has all these metabolic capacities that we must to engineer into S. cerevisiae…they have them already because they've evolved in that environment,” explains Jeffries.

The biofuel benefits of the new yeast, which was first discovered in 2006 by biologist Meredith Blackwell of Louisiana State University, are more than just theoretical. Jeffries, who founded biotechnology startup Xylome in 2007, is already looking for ways to produce the yeast on a commercial scale and integrate them into the existing bioenergy infrastructure.

Jeffries is interested in providing technologies to independent corn grain ethanol producers that will help them shift their focus to cellulosic feedstocks. For example, with S. passalidarum’s unique fermentation abilities, these companies could produce ethanol from the leaves and stalks of corn plants (corn stover) rather than the kernels. Jeffries predicts that this approach could help ethanol producers ameliorate ‘food versus fuel’ issues, as well as increase output by up to 50 percent.

"There are 122 independent ethanol production plants, each with an average capacity of about 50 million gallons per year, that produce 40 percent of all the ethanol in the U.S. from corn grain,” Jeffries says.

"They have the infrastructure, they have the distillation facilities, they have the fermentation facilities…so you don't have to make a lot of changes to these producers to be able to add corn stover as a feedstock."

Jeffries has also been in conversations with GLBRC collaborator MBI, a Michigan company specializing in the de-risking and scale-up of bio-based technologies. MBI is working to produce commercial quantities of corn stover that has been pretreated to make it more easily processed to ethanol. The pretreatment process, known as AFEXTM* was developed by GLBRC researcher Bruce Dale at Michigan State University.

A unique advantage of the AFEXTM process that it turns loose, dry cellulosic biomass into dense pellets—pellets that resemble corn grain in size and shape.

"If we could use AFEXTM pellets as a fermentation feedstock, that would provide an abundant, cost-effective sugar source for microbes to convert into biofuels like ethanol, as well as bio-based chemicals,” says MBI President and CEO Bobby Bringi.

Much of the rhetoric surrounding sustainable energy involves references to new technological frontiers and sweeping innovations. But Jeffries says that an industrial shift to cellulosic feedstocks—aided by yeast that can naturally process them to ethanol—is promising precisely because it would require only slight changes to the way grain ethanol producers currently operate.

"A lot of people think about biomass and bioenergy as major changes to the existing technology, and that's not really the way technology evolves—technology evolves at the margins,” he says.

"When you are going commercial with [a technology] it has to work...it can't work 90 percent of the time, or even 95 percent of the time. It has to work. So industry tends to look for incremental, rather than earth-shaking, changes.”

*AFEXTM is a registered trademark of MBI.