Last year, biofuel researchers at Michigan State University (MSU) published a study on an accelerated process for converting cellulosic—or non-food—plant biomass to ethanol in a quarter of the time it usually takes. This year, the MSU group is working with the University of Wisconsin-Madison to develop new fermentation microbes that can make that process even better.

The collaborators have recently published a paper in Biotechnology for Biofuels describing a novel method for screening yeast for strains that thrive in the unique environment of the accelerated process, which is called simultaneous saccharification and co-fermentation (SSCF).

The benefit of the SSCF process is the combination of the two major steps of cellulosic ethanol production: breaking apart biomass with a combination of heat and enzymes, and fermenting the resulting sugars into fuel.

The challenge? Enzymes are most active in much hotter environments than yeast can tolerate, so when the processing steps are combined into a single reactor, the yeast struggle to survive.

"One of the goals for this study was to develop a strain of Saccharomyces cerevisiae yeast that can perform SSCF efficiently," says Mingjie Jin, a GLBRC postdoctoral researcher at MSU and a corresponding author on the paper.

"Saccharomyces yeast can typically only ferment biomass into ethanol at up to 30 degrees Celsius [86 degrees Fahrenheit], but deconstruction enzymes operate at about 50 degrees C [122 degrees Fahrenheit]. So, we were trying to find a thermo-tolerant yeast strain," says Jin.

Heat tolerance isn’t the only characteristic the researchers are after; the perfect yeast strain for SSCF must also be resistant to toxins. Before cellulosic biomass is converted to ethanol, it goes through a process called pretreatment in which cell wall polymers are loosened to make it easier for enzymes to access the sugar polymers stored within. Unfortunately, pretreatment releases degradation products that are toxic to yeast.

"This is one of the major emphases of GLBRC research—to develop yeasts that can tolerate both degradation products and high temperatures," says Venkatesh Balan, an MSU associate professor of chemical engineering and materials science and an author on the paper.

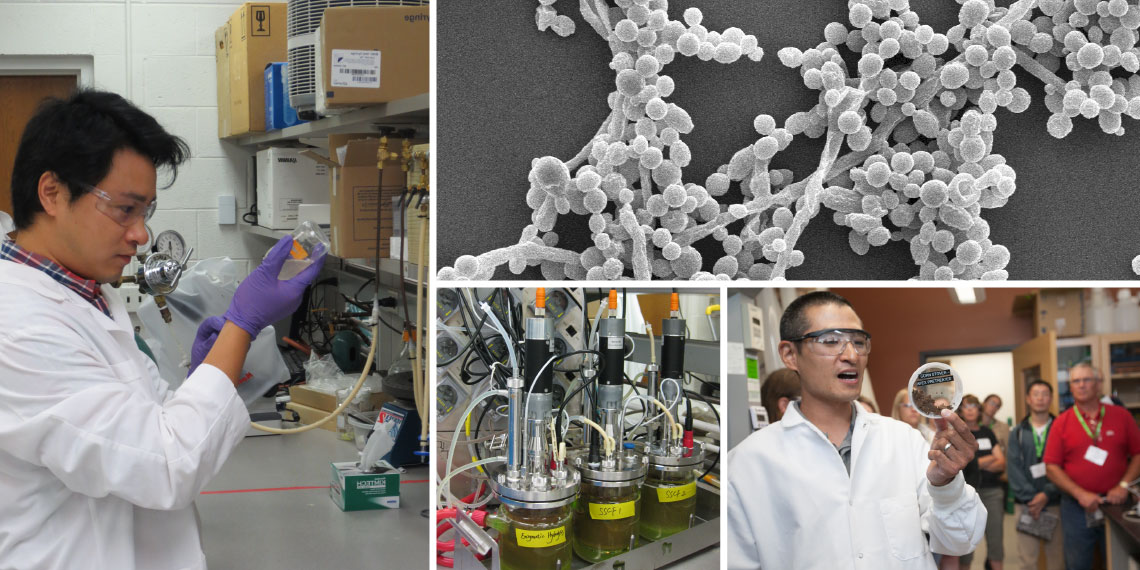

In order to develop the ideal fermentation microbe, Trey Sato, an associate scientist with the DOE Great Lakes Bioenergy Research Center (GLBRC) at the University of Wisconsin-Madison, screened more than 100 Saccharomyces strains isolated from both wild and industrial environments. Sato and his colleagues added each strain to pretreated corn leaves and stalks—also known as corn stover—to determine whether each could withstand both high temperatures and the toxic degradation products.

In the end, the screening resulted in the final selection of one exceptional Saccharomyces cerevisiae strain, dubbed GLBRCY0 (pictured left), which had been isolated from a banana plant.

“A unique aspect of this strain is its tolerance to multiple stress conditions,” says Sato. “There are a number of strains that displayed tolerance to high temperature or pretreatment toxins individually, but GLBRCY0 was one of few strains that could tolerate both stress-inducing conditions at the same time.”

Once Sato had identified the new strain, the team at MSU tested it in an SSCF reaction to convert pretreated corn stover into ethanol. At 35 degrees Celsius [95 degrees Fahrenheit], the new yeast performed significantly better than a known Saccharomyces baseline strain.

“The higher the temperature, the better the conversion,” says Balan. “Other processes usually take a week or more to produce ethanol, but by using this new strain in combination with SSCF, we can do everything in two days.”

Sato says that when the GLBRC was founded in 2007, the researchers did not have access to a yeast strain that could ferment under industrially relevant conditions. “Over the past several years, we've developed a strain that performs comparably to some strains that are currently being used by the biofuels industry,” says Sato.

The researchers’ success in identifying a thermo-tolerant yeast could have a big impact on ethanol processing, because high reaction temperatures have the dual advantages of reducing the chance of contamination and improving biomass breakdown.