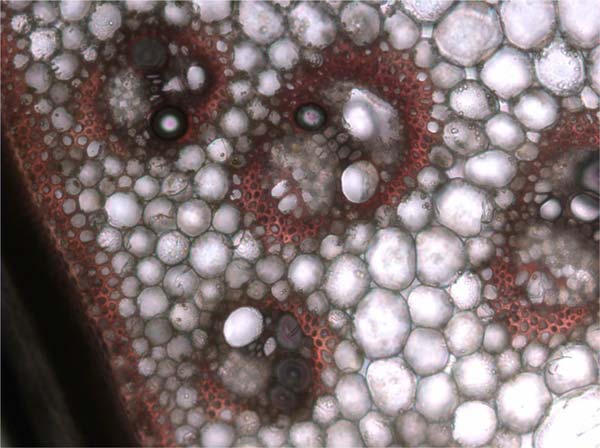

Waste not, want not: As this cross-section of a corn stem reveals, lignin—stained red—accounts for a significant portion of the plant tissue. GLBRC researchers are looking for ways to use that lignin to their advantage. Photo by John Sedbrook, Illinois State University.

Imagine if a lemonade stand vendor could market both the lemon peels and the juice. With this approach, he could sell more while wasting less. At the GLBRC, that’s exactly the kind of reasoning researchers are using to transform lignin from biofuel baggage into a benefit.

Lignin is an organic polymer that makes up a third of all plant biomass. While an advantage for plants, lignin poses a challenge for biofuels researchers, who must work out how to break down biomass for conversion to liquid transportation fuels.

“We are very focused on using sugars derived from plant cell walls for biofuel,” says GLBRC Science Programs Manager Steven Slater. “But if you’re going to make the process economical, you can’t throw away a third of the material.”

That’s why a GLBRC-wide effort is underway to identify ways to turn lignin into useful chemicals and materials that can be sold as ‘co-products’ of biofuel processing.

Until recently, bioenergy researchers had thought of lignin primarily as a barrier to large-scale biofuel production. Its structure is irregular and complex, and it varies among plant species. However, as scientists learn more about lignin’s chemical properties and commercial applications, they see great potential for this tricky compound to add value to biofuel reactions as co-products.

“What we’re trying to do is get energy out of biomass,” says Slater. “Ideally, we’d like to get all energy as liquid fuel, because you can put it into a jet or a car. But co-products are a way to add value to the process, and they allow you to take full advantage of all biomass.”

As a co-product, lignin can be harnessed for both fuel and non-fuel uses. During some biomass pretreatments, lignin can be extracted and used to coat animal feed pellets. This compacts the feed, making it easier to transport.

Lignin can also be burned to provide power, and since it is renewable and its combustion poses no significant environmental threat, it is an excellent candidate to drive ethanol-processing reactions.

In James Dumesic’s lab at UW–Madison, researchers have found that burning lignin for power isn’t the only way it can be used to improve the sustainability of biofuel production. Dumesic and his team have been converting lignin into organic solvents, which are used to process biomass into high-value chemicals traditionally derived from petroleum. Solvents represent a critical step in these chemically catalyzed reactions, and those derived from lignin can replace expensive, non-renewable chemicals.

“We have made a mixture of phenols from lignin and used them as solvents for our reactions, and they work very well,” says Dumesic. “They are just as efficient as petroleum-based solvents, and they alleviate the need to ship in solvents based on petroleum from a refinery site.”

While not classified as co-products because they are used in biomass processing reactions rather than sold, solvents are another example of lignin’s potential to make biofuel production systems less costly and more sustainable.

Researchers have also discovered that aromatics, the molecular building blocks of lignin, are key components of many common synthetic materials like plastics. As the only renewable source of aromatics, lignin could potentially be used to generate more sustainable forms of these materials.

In order to extract aromatics from lignin, David Hodge, a GLBRC researcher based at Michigan State University, is working on a pretreatment process that involves soaking plant biomass in hydrogen peroxide. This pretreatment approach, called alkaline hydrogen peroxide or AHP, shows promise for simultaneously ‘digesting’ biomass and extracting lignin for use in co-products.

“Generating sustainable compounds that could be used to produce analogs of terephthalic acid would be the holy grail for aromatics,” says Hodge. “This petroleum-derived chemical is used to produce certain plastics, which have a global market of several billion pounds per year. The aromatic acids released from the AHP process may offer some promise for producing these compounds.”

Ultimately, the true value of lignin co-products is that they lend flexibility to biofuel production and marketing. Since biomass is not currently considered a high-value commodity, it is fairly inexpensive to obtain large quantities for biofuel processing. However, if a large-scale cellulosic biofuel system were adopted, more feedstock would be demanded to keep up with energy production, which would result in rising feedstock prices.

“A feedstock might be free now, but if you develop it, it’s not going to stay free,” says Slater. He explains that producing fuels and valuable chemicals is an economic balancing act that can be affected by changing prices for feedstock and other inputs. Co-products are one way to give farmers and biofuel producers more choice when it comes to marketing.

“Co-products help the economics of the system, because the processed biomass has more than one market and producers aren’t beholden to one or the other,” says Slater. “It means you can send the various products of your process toward the most profitable endpoint at the time.”

In the end, decisions about what to do with co-products are all about making biofuel production environmentally and economically sustainable.

“There is a saying in the biofuel business that you can make anything out of lignin except money,” says Slater. That may be so, but with the innovations of GLBRC researchers, lignin may be transformed into something even more valuable: an approach to producing biofuel with benefits for both conservation and commerce.