Bruce Dale (left), head of Michigan State University’s Biomass Conversion Research Laboratory, and Bobby Bringi (right), CEO of MBI.

From patents to licenses to new industry partnerships, it's been a year of milestones for GLBRC as researchers combine basic research progress with commercial innovation.

Last summer, the Center was pleased to announce the first patent issued on a GLBRC technology, which was developed from research at Middleton, Wisconsin-based industry partner C5•6 Technologies. The pioneering piece of intellectual property protects a new heat-tolerant enzyme capable of breaking down the sturdy plant cell walls of cellulosic biomass for conversion to biofuel.

Produced by a species of bacteria called Dictyoglomus turgidum, the enzyme is found in the hot springs of Russia’s remote Kamchatka Peninsula. Microbial samples of D. turgidum from Kamchatka and the Obsidian Hot Spring at Yellowstone National Park were sequenced by the DOE Joint Genome Institute. At C5•6, Chief Scientific Officer Phil Brumm and his team have developed methods to produce the enzyme under laboratory conditions. The goal of these techniques is to generate the enzyme for use in large-scale biofuel production in the next few years.

The patent signifies the maturation of the GLBRC as a facilitator of technological innovation and transfer, and it is expected that the rate of intellectual property advancement will continue to accelerate following this milestone. “The GLBRC is making significant progress in the field of new enzymes,” says Brumm. “I think that this is just the tip of the iceberg, and that we’ll be seeing more patents in this area at the GLBRC in the next year or two.”

Following the announcement of Center’s first patent, the first license on a GLBRC technology was finalized in October. Developed in the laboratory of Conversion Area researcher Ron Raines, the technology has been licensed in an agreement between the Wisconsin Alumni Research Foundation (WARF) and biotechnology startup Hyrax Energy—the first company to emerge from GLBRC research.

The technology is a novel, renewable biofuel production method that uses ionic liquids to break down cellulosic biomass into fermentable sugars. Notably, the process does not require enzymes or costly pretreatments.

“Doing the entire conversion process in ionic liquids eliminates enzymes, pretreatment steps and harsh energy inputs and leads to a dramatic reduction in process complexity and capital intensity,” says Raines. “Hyrax has done considerable market research into the cost of ionic liquids and developed a process model that has been validated by third parties. The economic advantages of this approach far outweigh the costs.”

In addition to its scientific significance and economic advantages, the licensing of the new technology marks a major step toward commercializing this approach to biofuel production on an industrial scale.

On January 3, GLBRC’s ammonia fiber expansion pretreatment technology (AFEX™) became the focus of a new partnership between biotechnology de-risking and scale-up company MBI and industrial enzyme producer Novozymes.

The DOE awarded the two companies a combined $2.5 million to develop enzymes that can efficiently deconstruct AFEX™ -pretreated biomass, with the goal of releasing the fermentable sugars that drive ethanol production.

“There are two major challenges in converting agricultural biomass into biobased products,” said Allen Julian, chief business officer of MBI.

“One is the challenge of handling, storing and hauling low-density biomass to the refinery, and the other is the challenge of breaking down the biomass cost-effectively into its constituent sugars.”

AFEX™ tackles both these challenges. The process can be carried out in depots located near farms, with pretreated biomass becoming dense for easy storage and transportation. It also modifies the structure of plant cells, allowing enzymes to more easily break them down into simple sugars.

This partnership has the potential to further accelerate the application of the AFEX™ technology to large-scale biofuel production, following DOE’s previous award of $4.3 million to MBI to support the development of a commercial scale AFEX™ pilot reactor at its Lansing, Michigan facility.

At the UW–Madison Law and Entrepreneurship (L&E) Clinic, student attorneys are working directly with GLBRC scientists to help focus their research by generating 'freedom to operate analyses' identifying pre-existing publications and patents. With the L&E Clinic’s free services, researchers can visualize a research landscape in terms of what is known and unknown, and what areas are open to new discovery, allowing them to plan their work in a more strategic manner to produce results that are both novel and marketable.

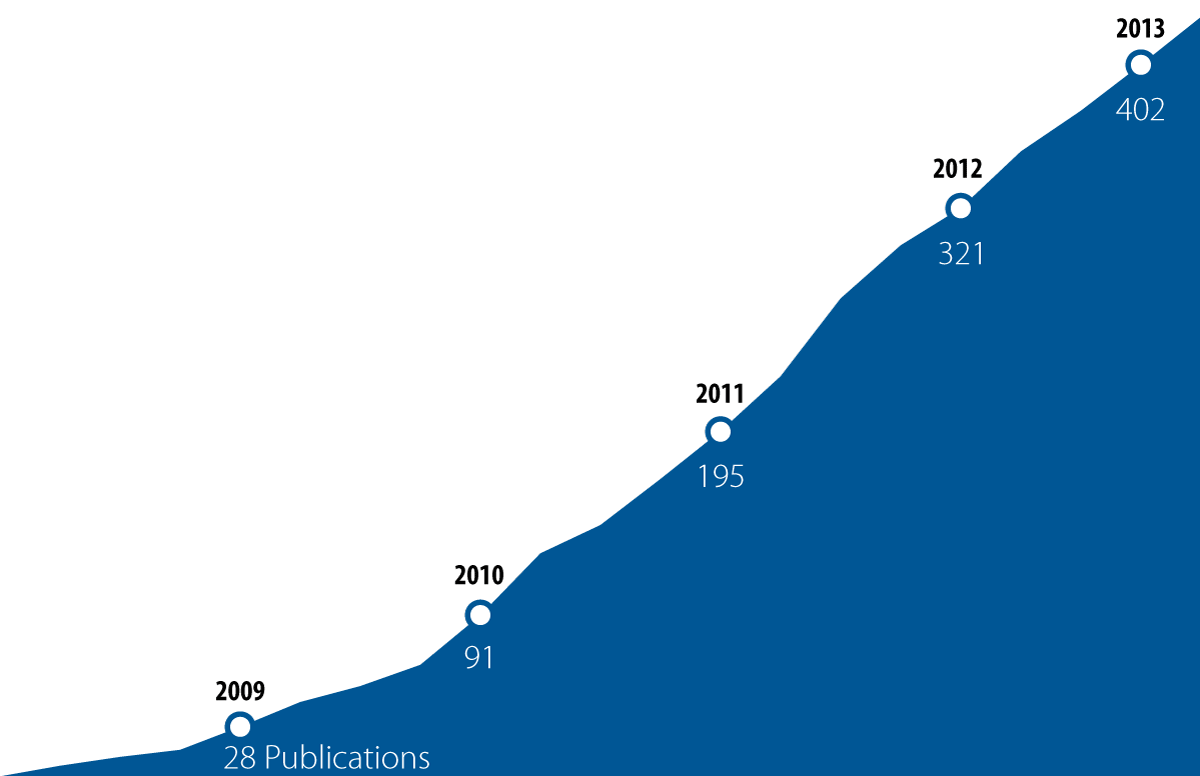

Over the past five years, an innovative approach to funding basic research has propelled GLBRC researchers into new collaborative teams. The results of those new partnerships have yielded tremendous impacts–both in scholarly publications and intellectual property.

400+ Publications

60 Invention Disclosures

58 Patent Applications

17 Licenses

Learn more about GLBRC technologies at glbrc.org/technologies